Low Calorie Gas Flares

Landfill Systems are worldwide innovators in low calorie gas flare technology. Our LC range of high performance gas flares has been specifically developed to address the need to safely dispose of low flows of landfill gas or flows of gas with low methane content, such as are increasingly found on aged landfill sites. Gas flows with a methane content as low as 12%CH4 (up to 100%CH4) and low flow ranges of 10m3/hr or above can be handled.

Since our first low calorie gas flare installation in 2010 the design of our LC flare has been perfected. We can now provide our customers with an optimum solution for safe and efficient degassing of old landfill sites.

Key Features

Flares delivered ready assembled and tested, ensuring a swift and dependable installation every time

‘Future proof’ design allows low cost downsizing.

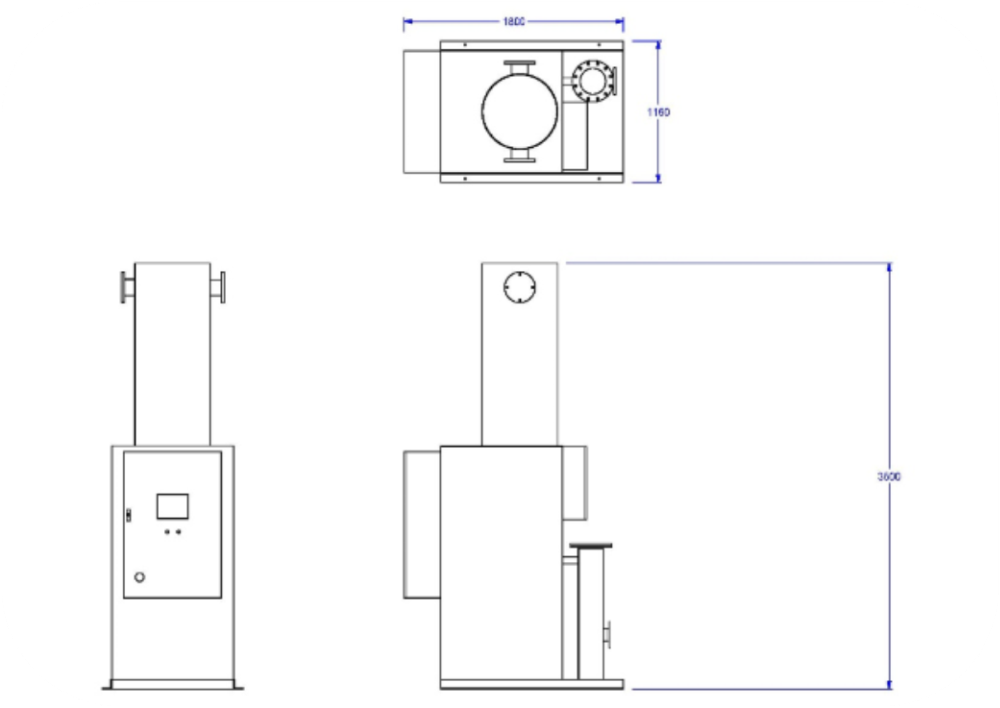

Compact design – only 1.8m(l) x 1.2m(w) x 3.6m(h)

Full operation, control and adjustment using your smartphone or PC as standard.

No additional fuel required (such as propane, etc.) for combustion or ignition.

Energy efficient

High temperature combustion (>1,000 °C)

Low emissions (better than EA LFTGN5 emissions limits )

Low methane content gas (from 11% CH4 up to 100%) can be handled

Low gas flow ranges (from 10Nm3/hr)

Low capital costs

Low operating costs

Low environmental impact

Low visual impact design

Designed for future renewable heat recovery / renewable power generation

High Quality construction

CHAS and ISO accredited company

The complete, compact and ready to go solution provided by Landfill Systems Low Calorie gas flare LC range has an aesthetically pleasing, simple design with a small footprint of only 1.8m x 1.2m. At only 3.6m high, it encompasses precise ideas to remove the ‘clutter’ of existing flare systems. The intelligently designed one-piece LC flare needs minimal site preparation. The compact design and low clutter look doesn't mean the LC gas flare scrimps on features though. Many accessories are included as standard, making Landfill Systems the first choice for Low Calorie Gas Flaring.

Our LC Gas Flares leave our workshop fully assembled and factory tested ensuring that once delivered, our engineers can simply and reliably install, connect and commission within a matter of hours. This ‘plug and play’ system is intended to work perfectly when first connected, with little or no adjustment required by the user.

The LC flare range provides a high level of ‘future proofing’. Should the landfill gas flow or methane level drop below the flare lower operating limit at some future point, the flare combustion system can be changed to suit the new conditions at a fraction of the cost of replacing the flare. For example, an LC500 can be easily down-sized to an LC250, just by changing the combustion system.

If you know the approximate flow and methane content of your gas stream, the capacity of the LC flare required can be easily assessed. As a rule of thumb, just multiply the flow (m3/hr.) by the % methane. Then multiply the result by 10 to give the capacity required in kW of heat (kWth). For example, a gas flow of 110m3/hr at 18% methane has an approximate theoretical calorific value of 198kWth. An LC200 low calorie flare would be the most suitable model.

Before (below) a Landfill Systems High Temperature 600m3/hr Enclosed Landfill Gas Flare installed in 2004, standing at 7.5m tall.

After (right) a Landfill Systems LC500 Enclosed Low Calorie Landfill Gas Flare installed in 2017, standing at 3.5m tall.

The before and after images were taken on the same site and the same concrete base! The existing flare was removed and replaced with our Low Calorie model LC500.